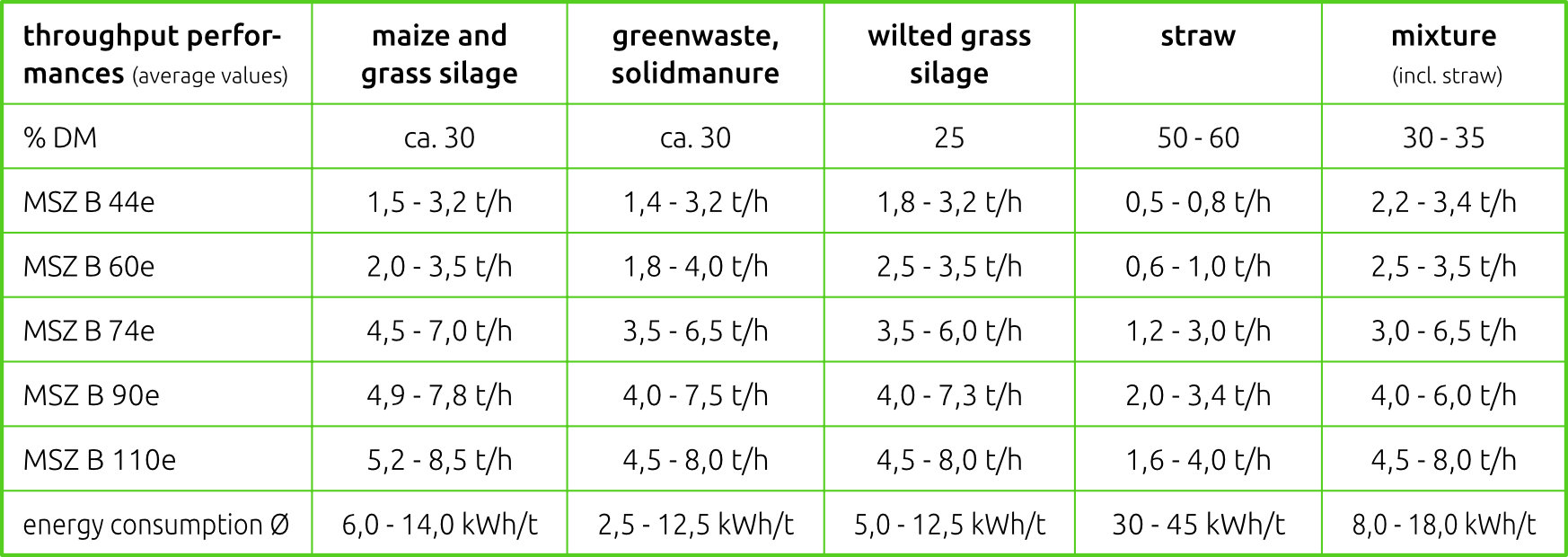

Our bioextruders serve to the desintegrate organic waste, wet waste, soaked manure, sludge rich in structure, old potatoes, apples, aqueous meat waste, bones and municipal waste. The extended, series of bioextruders increases the degree of disintegration.

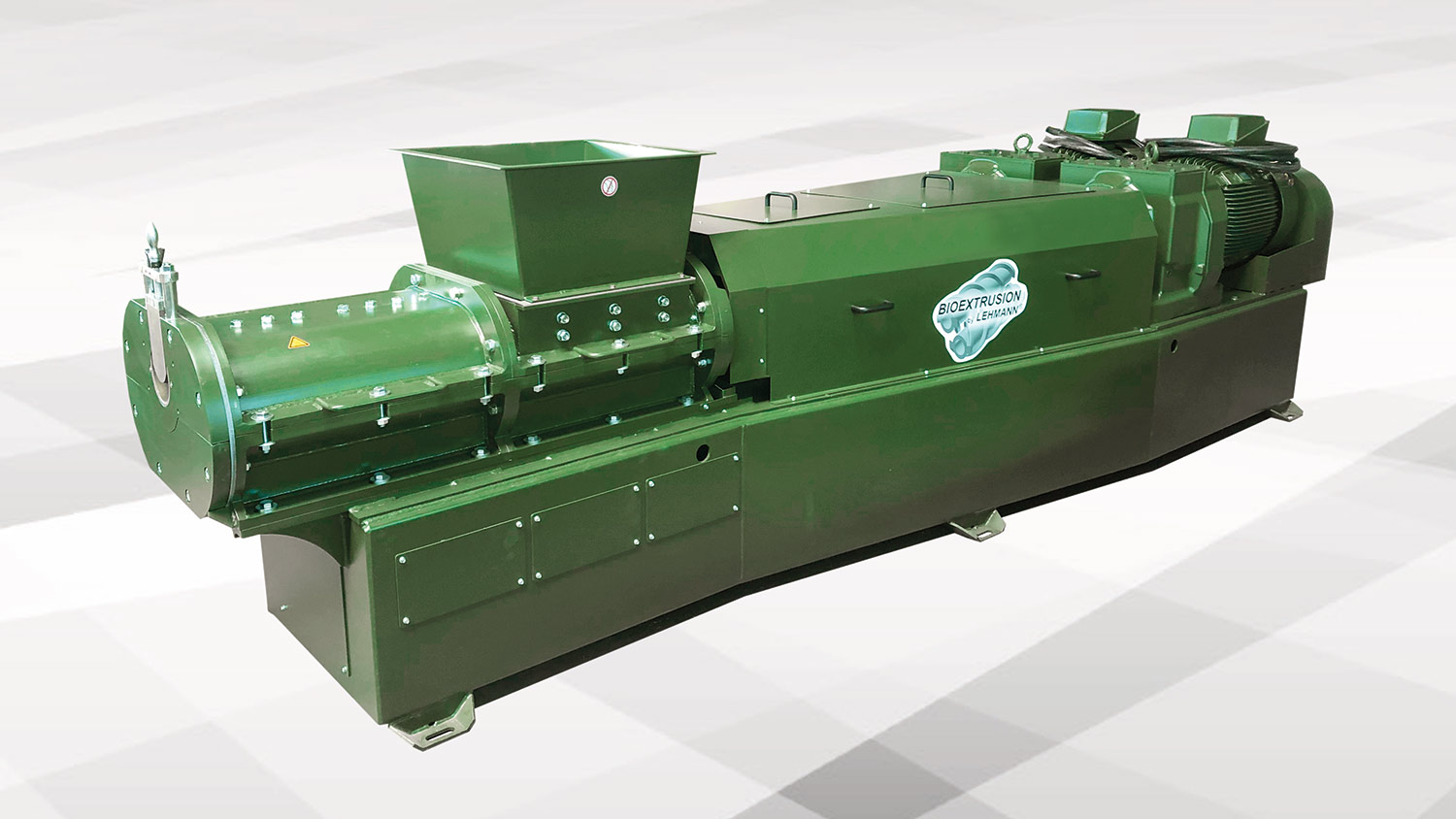

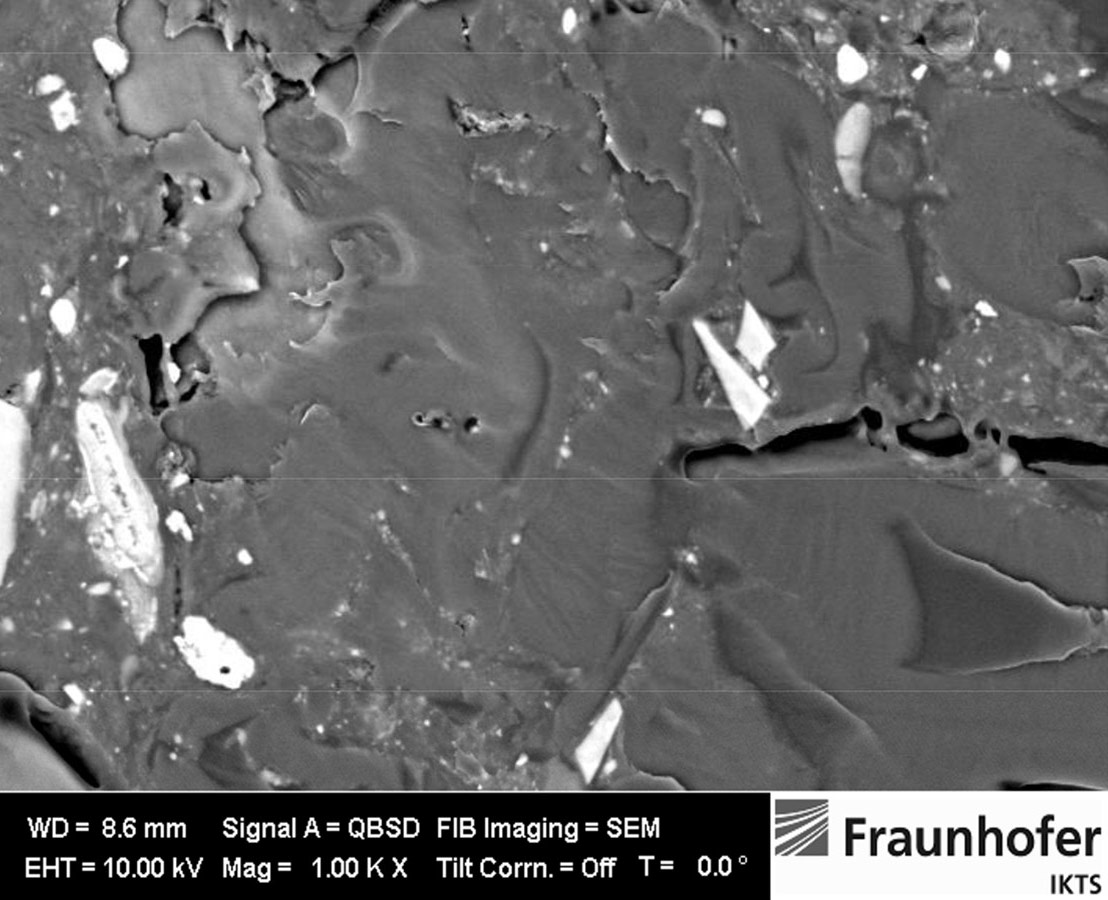

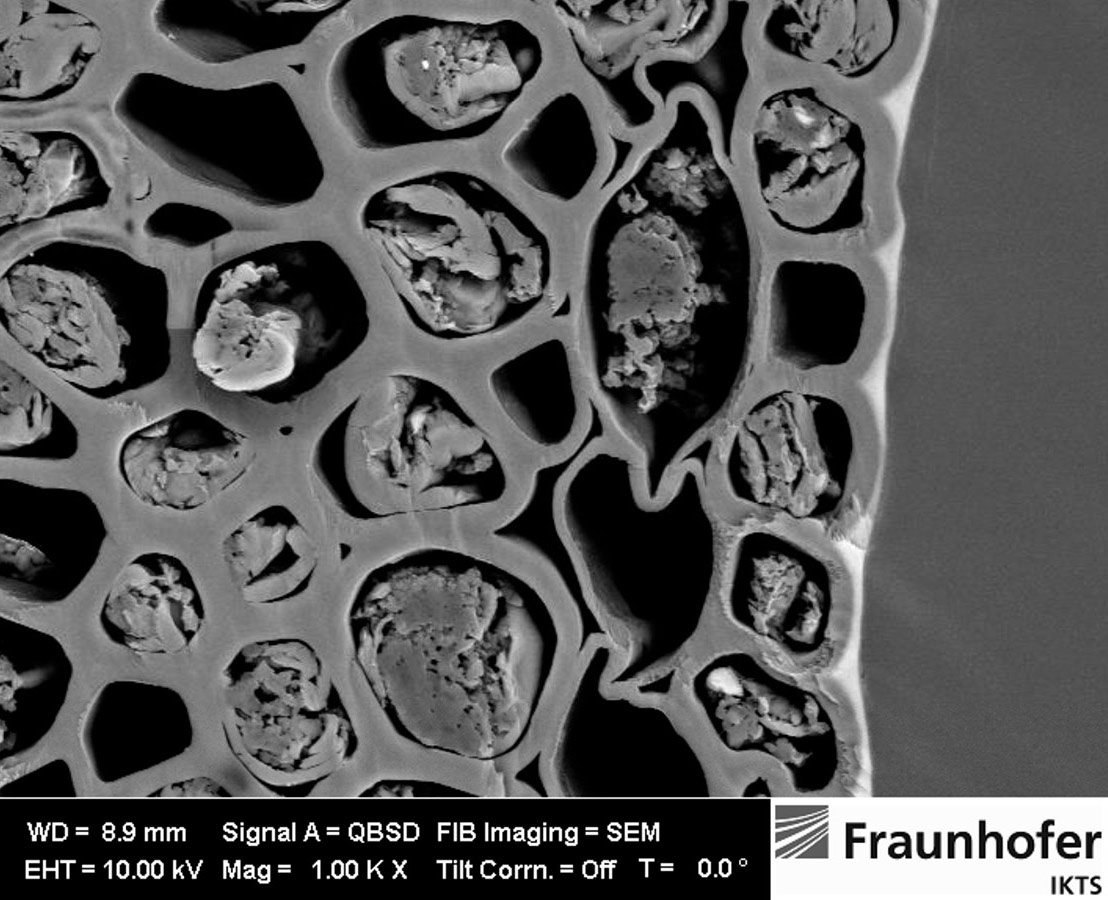

The disintegration process of Bioextrusion developed by us is based on thermomechanical digestion and has proven to be very effective for the material and energetic use of fibre plants. In a twin-screw extruder, the substrate is disintegrated into the cell structure by pressure and thus higher temperature, caused by changing loads and multiple pressure/relief cycles in the device. The biogas yield is increased by better biochemical availability and an increased surface area. The modular design of the extruders allows them to be used in a variety of ways as the heart of processing different materials with different processing objectives.

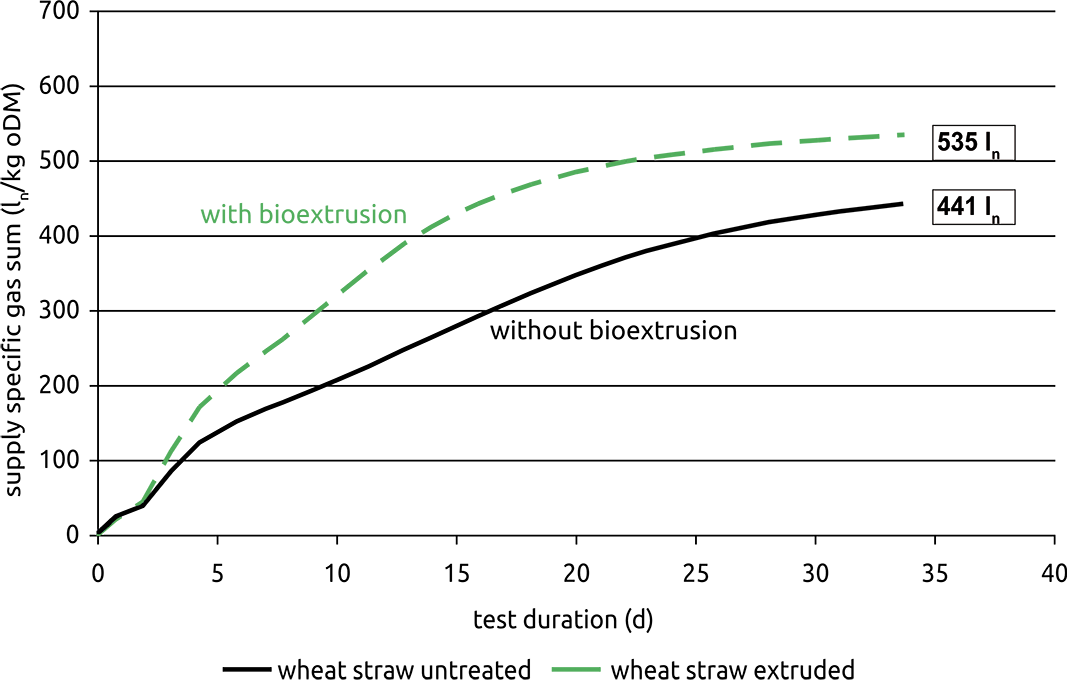

An essential advantage of bioextrusion is the increase of productivity and of the degradation rate by 10 to 40 % in biogas plants. Furthermore the energy consumption amounts to a maximum of 10% of the additional reached yield. Plants which are not working to capacity can process more substrates and produce more biogas (increase in digestion load). The construction of smaller, more compact plants or the retrofitting of existing plants thus is possible. Above all, however, the possible use of substrates with a high lignin and dry matter content, such as straw, grass, landscape conservation material and manure, which were previously difficult to use, is a remarkable advantage of bioextrusion.

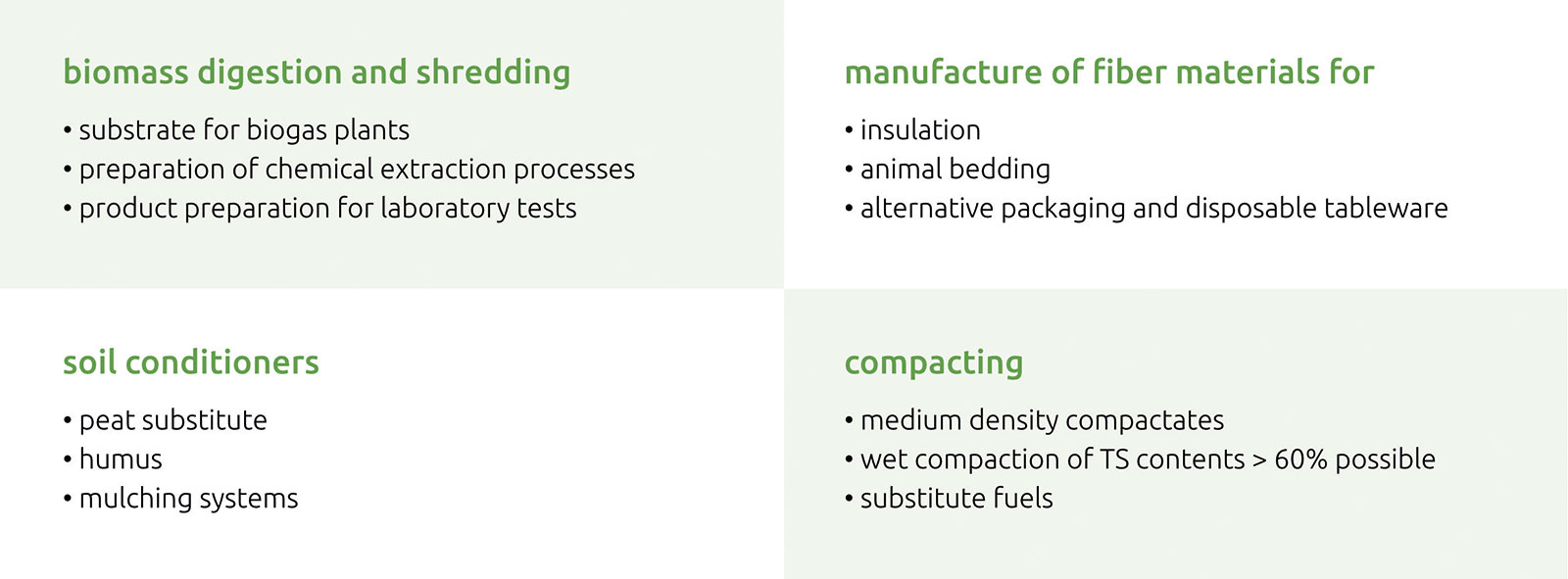

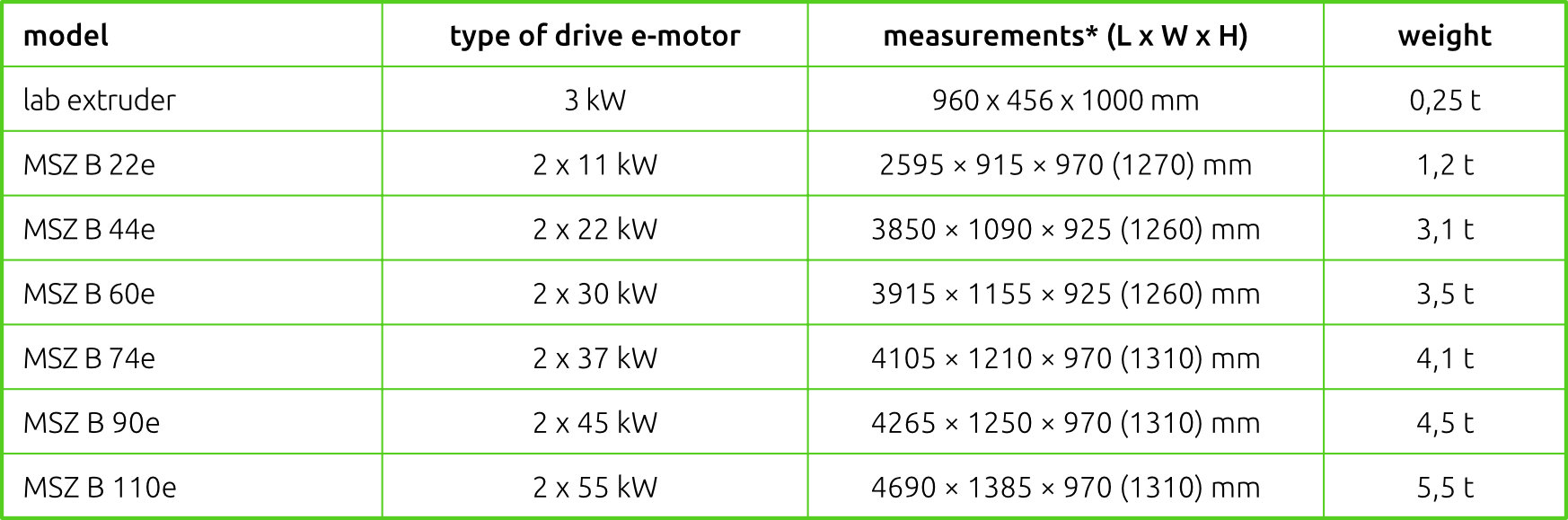

The extruder can be used in many different ways. It serves not only for thermomechanical digestion but also for plasticizing and compacting, for mixing and compounding, for dewatering and material separation as well as for the production of feed pellets for pigs, chickens and small animals. Different extruder models are available depending on the application and desired throughput.

LMEngineering GmbH

Jocketa - Bahnhofstraße 34, 08543 Pöhl, Germany

phone: +49 - 37439 - 74439 • fax: +49 - 37439 - 7449039 • e-mail: info@lmengineering.de