Whether as a peat substitute, insulation material or greening substrate, the potential uses of wood pulp are diverse and important, especially for a sustainable and climate-neutral future. We are your competent partner and producer of a wood pulping plant adapted to your needs. From feed technology and removal of impurities to patented bioextrusion, we place our complete expertise in this field of environmental technology at your disposal.

Shredded wood or other biomass is loaded into the dosing machine as feedstock and fed onto the vibro-conveyor according to the throughput of the plant for an equalised flow. The belt magnet separates out ferrous metals. In the subsequent float-sink box, heavy items sink to the bottom and discharged, while the wood and cellulosic substrates float and are moistened. Non-ferrous metal detection and rejection of impurities takes place at the detector.

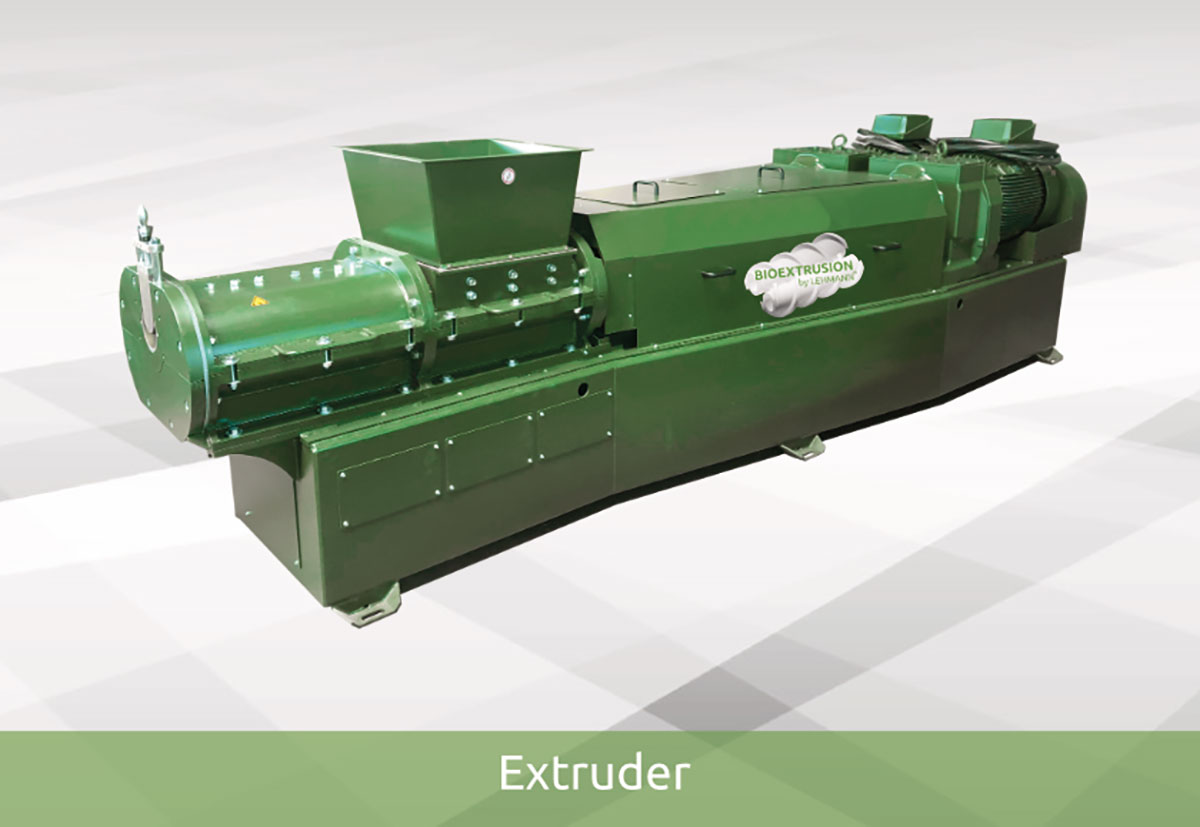

After dosing and removal of impurities, the material is conveyed into the twin-screw extruder. Due to the counter-rotating motion of the screws, the material is subjected to constantly changing pressures and temperatures, and is thereby compacted, fulled and pulped. In addition, there is a "steam explosion effect" which occurs when the water contained in the material evaporates explosively and tears the cell structure apart from the inside due to alternating compression and relaxation zones. Disintegration down to the cell structure takes place. In the process, substances are dissolved, plasticised, broken down, mixed and change their properties.

LMEngineering GmbH

Jocketa - Bahnhofstraße 34, 08543 Pöhl, Germany

phone: +49 - 37439 - 74439 • fax: +49 - 37439 - 7449039 • e-mail: info@lmengineering.de