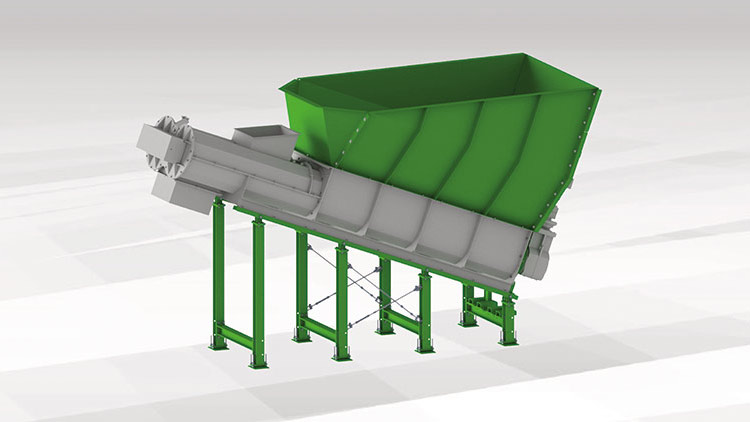

Our dosing technology uses the different characteristics of special conveying technology to adapt the system as best as possible to the respectiv material of the customer. Discharge quantity and size also determine the design of the system and are optimised according to the customer's requirements.

The most common impurities in biogas plants are stones and metals. In order to ensure a trouble-free supply of substrates to the biogas plant, we therefore offer detectors for ferrous and non-ferrous metals in addition to our conveyor technology. A high search sensitivity for all metals is just as standard as an effective suppression of disturbances from the environment.

A beater vibrates the conveyor's flexible belt, causes stones and other impurities to fall back and not to be introduced into the system. This not only ensures steady substrate supply, but also reduces wear costs.

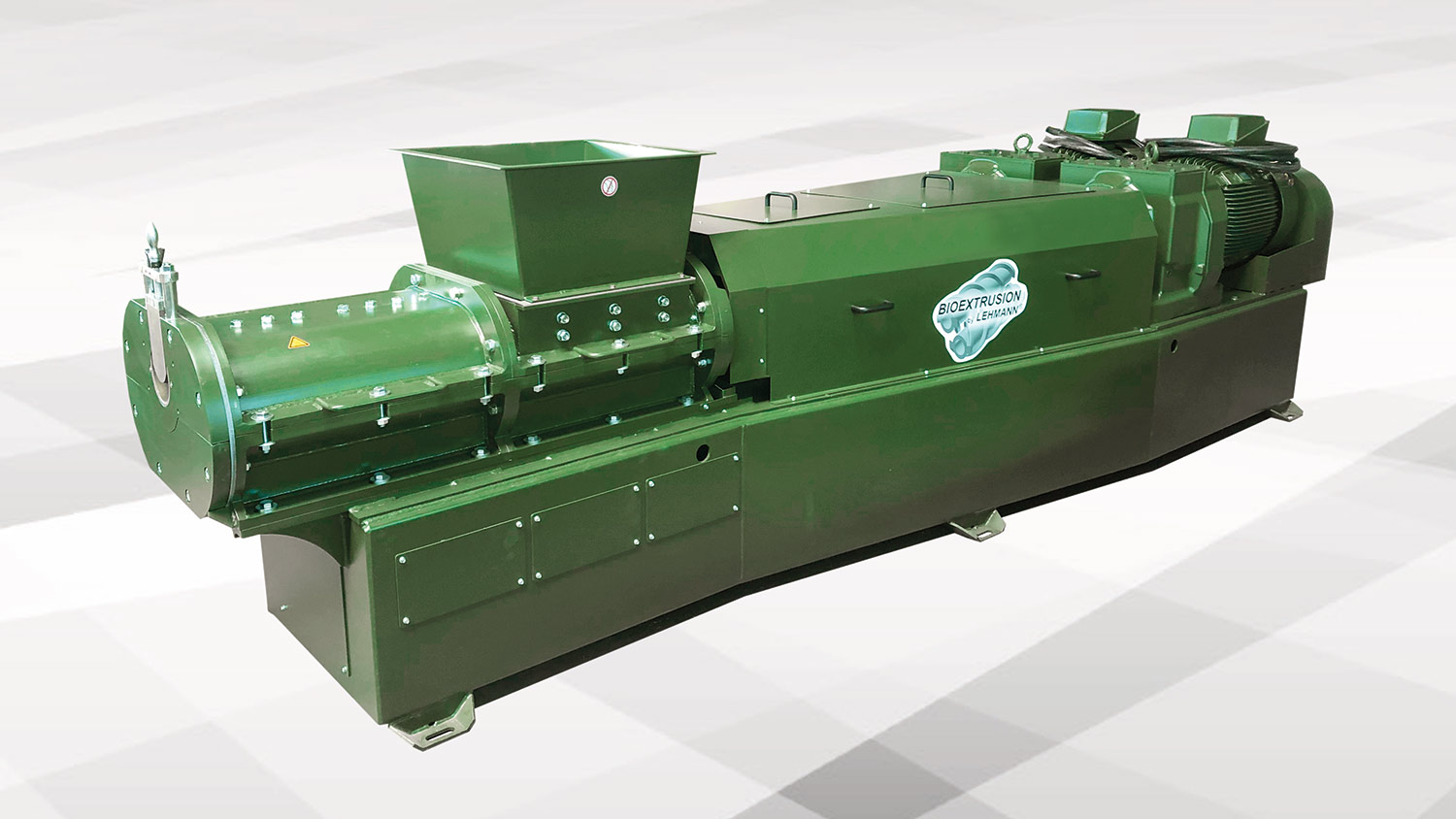

The disintegration process of Bioextrusion developed by us is based on thermomechanical digestion and has proven to be very effective for the material and energetic use of fibre plants. In addition to an increase in gas production in biogas plants, extrusion technology offers various other applications in the fields of biomass distintegration and size reduction, the production of fibrous materials for various applications, the production of soil conditioners and compaction.

further information: extrusion technology

The conveyor technology of LMEngineering offers various solutions, for example chain, belt or screw conveyors. They can also be implemented as mobile solutions. Depending on performance, quantity, gradient and material to be conveyed, the system is designed according to the customer's requirements and optimised for the specific application.

LMEngineering GmbH

Jocketa - Bahnhofstraße 34, 08543 Pöhl, Germany

phone: +49 - 37439 - 74439 • fax: +49 - 37439 - 7449039 • e-mail: info@lmengineering.de